The cost of metallic diamond alloy parts is estimated at around 70 USD/kg, making them cheaper than Co-WC-based hard metals, which cost 300 USD/kg. Another comparative advantage over WC-Co is the alloy’s significantly lower density. This feature is crucial for applications in pin mills as it greatly reduces energy consumption.

It is important to highlight that Metallic Diamond alloys do not contain cobalt, a toxic and scarce metal with an uncertain supply chain.

The alloy can be supplied in powder form or small shaped parts tailored to specific applications.

The Metallic Diamond, composed of up to seven distinct metallic elements, represents a new class of metallic materials.

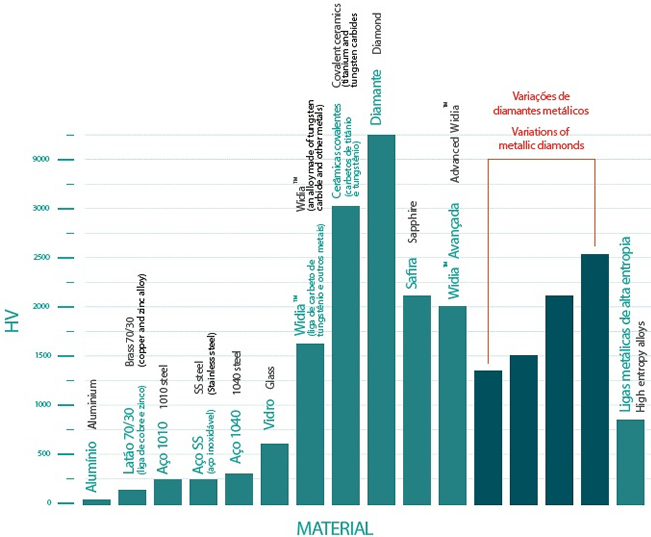

This material boasts the highest hardness ever developed by humanity (up to 2500 kgf/mm²), along with reasonable fracture toughness (10 to 25 MPa·m¹/²). The alloys are crystalline metallic materials with good high-temperature stability and excellent corrosion resistance.

The potential applications are vast, spanning various components subjected to heavy abrasion and wear, as well as high temperatures and degradation. Preliminary results have shown that turning inserts made with these alloys outperform hard metals and ceramics in steel machining. The products can be ground into high-activity powders and sintered into dense bodies, paving the way for industrial shaping of components.